by Karim Nice

Introduction to Ignition System

The internal combustion engine is an amazing machine that has evolved for more than 100 years. It continues to evolve as automakers manage to squeeze out a little more efficiency, or a little less pollution, with each passing year. The result is an incredibly complicated, surprisingly reliable machine.

Other How Stuff Works articles explain the mechanics of the engine and many of its subsystems, including the fuel system, cooling system, camshafts, turbochargers and gears. One could argue that the ignition system is where it all comes together, with a perfectly timed spark.

In this article, we'll learn about ignition systems, starting with spark timing. Then we'll look at all of the components that go into making the spark, including spark plugs, coils and distributors. And finally, we'll talk about some of the newer systems that use solid-state components instead of the distributor.

Ignition System Timing

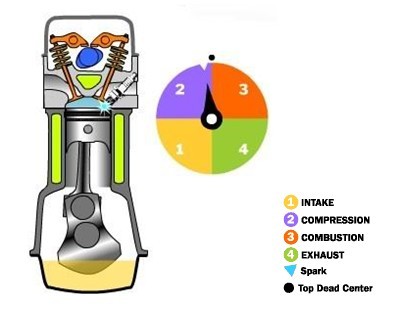

The ignition system on your car has to work in perfect concert with the rest of the engine. The goal is to ignite the fuel at exactly the right time so that the expanding gases can do the maximum amount of work. If the ignition system fires at the wrong time, power will fall and gas consumption and emissions can increase.

When the fuel/air mixture in the cylinder burns, the temperature rises and the fuel is converted to exhaust gas. This transformation causes the pressure in the cylinder to increase dramatically and forces the piston down.

In order to get the most torque and power from the engine, the goal is to maximize the pressure in the cylinder during the power stroke. Maximizing pressure will also produce the best engine efficiency, which translates directly into better mileage. The timing of the spark is critical to success.

There is a small delay from the time of the spark to the time when the fuel/air mixture is all burning and the pressure in the cylinder reaches its maximum. If the spark occurs right when the piston reaches the top of the compression stroke, the piston will have already moved down part of the way into its power stroke before the gases in the cylinder have reached their highest pressures.

To make the best use of the fuel, the spark should occur before the piston reaches the top of the compression stroke, so by the time the piston starts down into its power stroke the pressures are high enough to start producing useful work.

Work = Force * Distance

In a cylinder:

Force = Pressure * Area of the piston

Distance = Stroke length

So when we're talking about a cylinder, work = pressure * piston area * stroke length. And because the length of the stroke and the area of the piston are fixed, the only way to maximize work is by increasing pressure.

The timing of the spark is important, and the timing can either be advanced or retarded depending on conditions.

The time that the fuel takes to burn is roughly constant. But the speed of the pistons increases as the engine speed increases. This means that the faster the engine goes, the earlier the spark has to occur. This is called spark advance: The faster the engine speed, the more advance is required.

Other goals, like minimizing emissions, take priority when maximum power is not required. For instance, by retarding the spark timing (moving the spark closer to the top of the compression stroke), maximum cylinder pressures and temperatures can be reduced. Lowering temperatures helps reduce the formation of nitrogen oxides (NOx), which are a regulated pollutant. Retarding the timing may also eliminate knocking; some cars that have knock sensors will do this automatically.

Next we'll go through the components that make the spark.

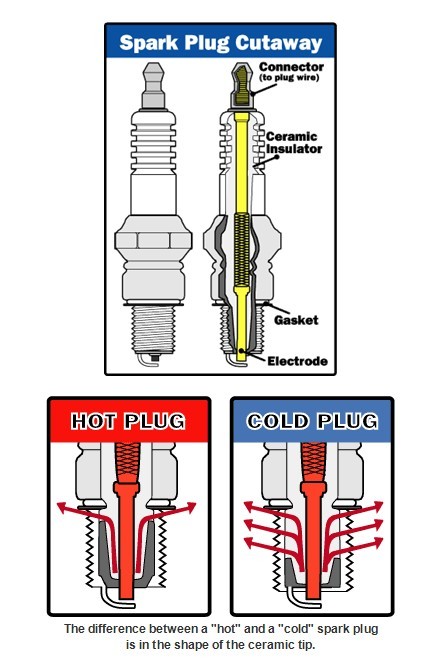

Spark Plug

The spark plug is quite simple in theory: It forces electricity to arc across a gap, just like a bolt of lightning. The electricity must be at a very high voltage in order to travel across the gap and create a good spark. Voltage at the spark plug can be anywhere from 40,000 to 100,000 volts.

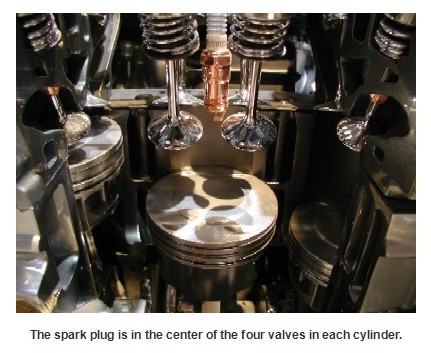

The spark plug must have an insulated passageway for this high voltage to travel down to the electrode, where it can jump the gap and, from there, be conducted into the engine block and grounded. The plug also has to withstand the extreme heat and pressure inside the cylinder, and must be designed so that deposits from fuel additives do not build up on the plug.

Spark plugs use a ceramic insert to isolate the high voltage at the electrode, ensuring that the spark happens at the tip of the electrode and not anywhere else on the plug; this insert does double-duty by helping to burn off deposits. Ceramic is a fairly poor heat conductor, so the material gets quite hot during operation. This heat helps to burn off deposits from the electrode.

Some cars require a hot plug. This type of plug is designed with a ceramic insert that has a smaller contact area with the metal part of the plug. This reduces the heat transfer from the ceramic, making it run hotter and thus burn away more deposits. Cold plugs are designed with more contact area, so they run cooler.

The carmaker will select the right temperature plug for each car. Some cars with high-performance engines naturally generate more heat, so they need colder plugs. If the spark plug gets too hot, it could ignite the fuel before the spark fires; so it is important to stick with the right type of plug for your car.

Next, we'll learn about the coil that generates the high voltages required to create a spark.

Ignition System Coil

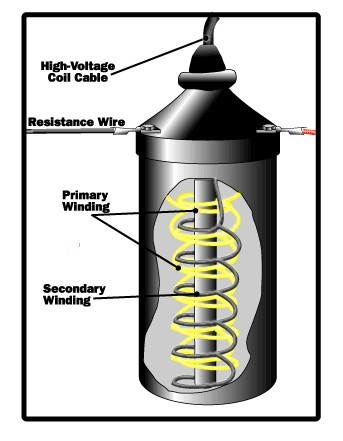

The coil is a simple device -- essentially a high-voltage transformer made up of two coils of wire. One coil of wire is called the primary coil. Wrapped around it is the secondary coil. The secondary coil normally has hundreds of times more turns of wire than the primary coil.

Current flows from the battery through the primary winding of the coil.

The primary coil's current can be suddenly disrupted by the breaker points, or by a solid-state device in an electronic ignition.

If you think the coil looks like an electromagnet, you're right -- but it is also an inductor. The key to the coil's operation is what happens when the circuit is suddenly broken by the points. The magnetic field of the primary coil collapses rapidly. The secondary coil is engulfed by a powerful and changing magnetic field. This field induces a current in the coils -- a very high-voltage current (up to 100,000 volts) because of the number of coils in the secondary winding. The secondary coil feeds this voltage to the distributor via a very well insulated, high-voltage wire.

Finally, an ignition system needs a distributor.

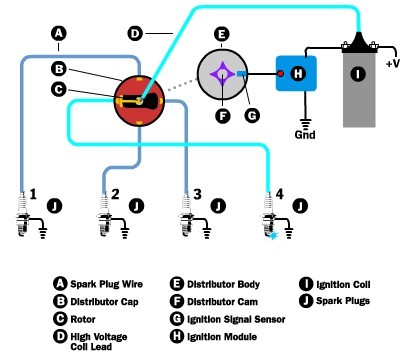

Ignition System Distributor

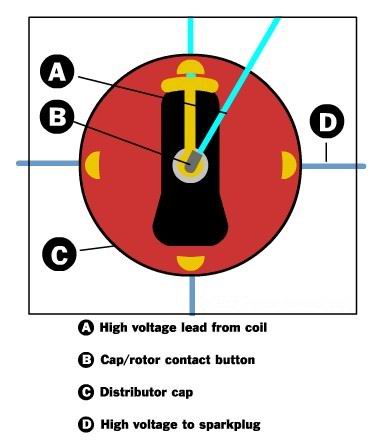

The distributor handles several jobs. Its first job is to distribute the high voltage from the coil to the correct cylinder. This is done by the cap and rotor. The coil is connected to the rotor, which spins inside the cap. The rotor spins past a series of contacts, one contact per cylinder. As the tip of the rotor passes each contact, a high-voltage pulse comes from the coil. The pulse arcs across the small gap between the rotor and the contact (they don't actually touch) and then continues down the spark-plug wire to the spark plug on the appropriate cylinder. When you do a tune-up, one of the things you replace on your engine is the cap and rotor -- these eventually wear out because of the arcing. Also, the spark-plug wires eventually wear out and lose some of their electrical insulation. This can be the cause of some very mysterious engine problems.

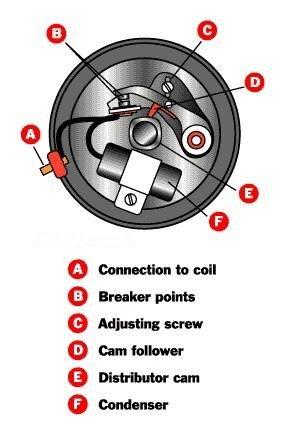

Older distributors with breaker points have another section in the bottom half of the distributor -- this section does the job of breaking the current to the coil. The ground side of the coil is connected to the breaker points.

A cam in the center of the distributor pushes a lever connected to one of the points. Whenever the cam pushes the lever, it opens the points. This causes the coil to suddenly lose its ground, generating a high-voltage pulse.

The points also control the timing of the spark. They may have a vacuum advance or a centrifugal advance. These mechanisms advance the timing in proportion to engine load or engine speed.

Spark timing is so critical to an engine's performance that most cars don't use points. Instead, they use a sensor that tells the engine control unit (ECU) the exact position of the pistons. The engine computer then controls a transistor that opens and closes the current to the coil.

In the next section, we'll take a look at an advance in modern ignition systems: the distributorless ignition.

Distributorless Ignition

In recent years, you may have heard of cars that need their first tune-up at 100,000 miles. One of the technologies that enables this long maintenance interval is the distributorless ignition.

The coil in this type of system works the same way as the larger, centrally-located coils. The engine control unit controls the transistors that break the ground side of the circuit, which generates the spark. This gives the ECU total control over spark timing.

Systems like these have some substantial advantages. First, there is no distributor, which is an item that eventually wears out. Also, there are no high-voltage spark-plug wires, which also wear out. And finally, they allow for more precise control of the spark timing, which can improve efficiency, emissions and increase the overall power of a car.

» More Information