Program Overview:

Lean manufacturing which is often known simply as "Lean", is a generic process management philosophy derived mostly from the Toyota Production System (TPS). It is a powerful method that allows organizations to improve the productivity, efficiency, and quality of their products or services. Companies today, from a wide range of industries, government agencies and other areas are finding ways to apply the principles of lean as a means of producing goods and delivering services that creates value for the customer with the minimum amount of waste and the highest level of quality. The simulation-based, hands-on workshop will present you with essential principles, tools and applications of Lean in the manufacture environment.

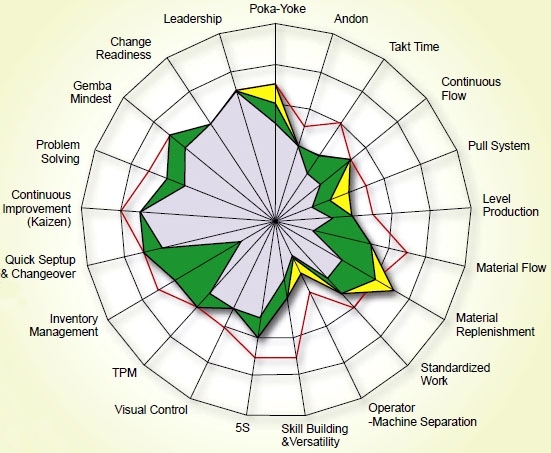

Fig 1. Lean Manufacturing Program

Objectives:

Upon the completion of this program, the participants will be able to:

•Understand the Lean Principles and Tools

•Discuss the Lean Deployment Strategy and Framework

•Conduct Value Stream Maps of the Current State and Develop a Future State

•Identify Wastes and use critical Lean Tools to Eliminate Wastes

•Define the Improved Flow and Process in Simulated Manufacturing Environments.

•Apply the Lean Principles and Tools at their Workplace and Lead Projects.

•Improve the Overall Efficiency of the Factory Operations including the Support Areas.

Program Participants:

This program is designed for the managers, engineers and professionals working in the manufacturing environment, who want to equip themselves with the knowledge and skills necessary to be effective change Agents and Lean Advocates and Practitioners in their organization.

Program Outline:

Module 1: Introduction to Lean Manufacturing

•Why ¡°Lean¡±?

•History of lean

•5 principles of lean

•Lean manufacturing and Toyota Production System

•Lean and six sigma

Module 2: Waste Identification

•Define Customer Value-add and Business-Value add

•7 wastes in Manufacturing

•Identify the causes of 7 wastes

•Muda, Mura & Muri

Module 3: Value Stream Mapping

•What is value stream?

•The purpose of a Value Stream Map (VSM)

•Develop a Current State Value Stream Map of a process

•Analyze a Current State Map for quick wins

•Develop a Future State Map

•How to implement VSM?

Module 4: 5S-Workplace Organization

•Why 5S?

•What is 5S?

•Step by step 5S Implementation

Module 5: Total Productive Maintenance

•What is TPM & TPM Metrics?

•Six Losses of Equipment and OEE calculation

•4 phases of TPM

•7 steps of TPM

Module 6: Standardization

•What is an standardized system?

•Advantages of standardization

•Degrees of standardization

•Development of Standard Operation Procedure

Module 7: Visual Management

•Why Visual Management?

•Benefits of Visual Management

•Levels and steps of Visual Management

•Tools of Visual Display and Visual Control

Module 8: PokaYoke

•Poka Yoke Philosophy

•Error & Defect

•Poka Yoke Devices

•Poka Yoke System

Module 9: Flow and Work Cell Design

•What¡¯s Flow?

•Traditional layout & Lean layout

•What¡¯s Workcell?

•Prerequisite of Workcell

•9 steps for Workcell Design

Module 10: Standardized Work

•What is Standardized Work?

•Difference between Work Standard & Standardized Work

•Steps of Standardized Work

Module 11: SMED(Quick Change Over)

•What is SMED?

•Waste during Change Over (C/O) or Setups

•Benefits gained from reducing C/O times

•Procedures for observing & recording internal & external C/O activities

•Methods for reducing C/O times

Module 12: Pull System Introduction

•What is ¡°Pull¡±?

•Prerequisites of Pull System

•Order Analysis

•How to choose different Pull systems?

•Pull System Rules

•Introduction of Supermarket Model

Module 13: Kanban

•What¡¯s Kanban?

•Kanban Functions

•Kanban Types and Application

•Kanban Calculation

Module 14: Pacemaker & Heijunka

•Determine Pacemaker

•Why Heijunka?

•Heijunka Elements &Sequence

•Heijunka Box

•Water Spider Route

•Heijunka Application

Module 15: Upstream Process Pull

•Manage upstream process from Pacemaker

•Trigger Withdrawal Kanban

•Control upstream batch process from Supermarket

Module 16: Kaizen

•What is Kaizen?

•Kaizen Spirit

•Main Kaizen Activity

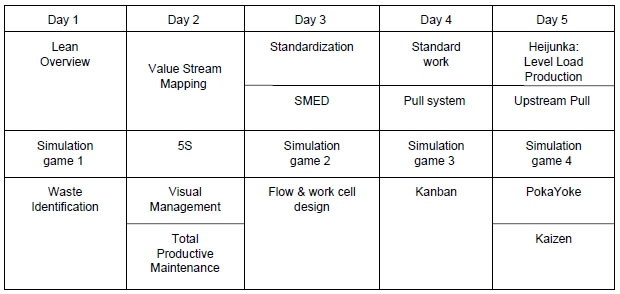

Fig 2. Lean Manufacturing Program Design

Program Length: 5 days workshop

The workshop simulation exercise introduction:

The main purpose of the Lean simulation exercises is to enable the participants to master the concept and tools learned in the workshop. Participants can learn it better by simulating a simple manufacture process similar to that in a plant, immediately upon studying the basic concept, methods and tools of lean. The simulation is run using a few rounds with step by step approach and focus to improve the flow of a simulated factory, it will also help the participants to understand the pull system by using Kanban.

» More Information