Introduction

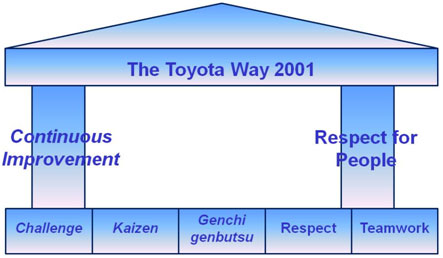

"The Toyota Way can be briefly summarized through the two pillars that support it: Continuous improvement and Respect for people"

Fig 1. The Toyota Way 2001

Lean Manufacturing is the term coined by Womack and Jones in their seminal book ※The machine that changed the world§ to describe the Toyota Production System. The focus on manufacturing has broadened to service activities and the public sector and now we talk about ※lean thinking§ or just ※lean§. There have been numerous publications about lean processes and tools many of these don*t provide the context in which ※lean§ is at its most effective. The model presented in the ※Toyota Way 2001§ provides the context.

The top two pillars are Continuous Improvement and Respect for People; all Toyota members, at every level, are expected to use these values in their daily work and interactions.

Respect for People is a broad commitment. It means respect for all people touched by Toyota including employees, customers, investors, suppliers, dealers, the communities in which Toyota operates and society at large. It has two sub categories:

Respect 每 we respect others, make every effort to understand each other, take responsibility and do our best to build mutual trust.

Teamwork 每 we stimulate personal professional growth, share the opportunities of development and maximize individual and team performance

Continuous Improvement is defined as ※we are never satisfied with where we are and always improve our business by putting forth our best ideas and efforts§. It has three sub categories to complete the house:

Challenge 每 we form a long-term vision meeting challenges with courage and creativity to realize our dream

Kaizen 每 we improve our business operations continuously, always driving for innovation and evolution

Genchi Genbutsu 每 we believe in going to the source to find the facts to make correct decisions, build consensus and achieve goals at our best speed.

Many organizations use the lean processes and tools but do not achieve the gains that Toyota has achieved. While there are many reasons for this certainly one is that the ※respect for people§ value is no where near as strong in many ※lean§ organizations as it is at Toyota. Site visits and tours will demonstrate the principles, processes and tools but to really understand you have to look beyond the visible activities to the attitudes, behaviors and values embedded in the people. While the principles of the culture of a lean organization can be taught implementation is all together another proposition.

History

After the Allied victory of World War II, the Japanese industrialists studied American production methods with particular attention to Ford practices and the Statistical Quality Control practices of Ishikawa, Edwards Deming, and Joseph Juran.

At Toyota Motor Company (1949 and 1975), Taichii Ohno and Shigeo Shingo established a new approach called Toyota Production System (TPS) or Just In Time JIT

TPS incorporated Takt Time ideas to Ford ideas of Continuous Flow and added the critical dimension of Flexibility to make high Quality products at the lowest Cost in wide Variety in Small Batches with very Short Lead Time

Ohno & Shigeo learned of the American Supermarket System and how a version was being implemented at Lockheed. The supermarket concept was to place out a small quantity of all the products your customer might want and replenish those items as they are used〞a Pull system.

Shingo, at Ohno's suggestion, went to work on the Setup and Changeover problem. Reducing setups to minutes and seconds (SMED Single Minute exchange of Dies) allowed small batches and an almost continuous flow like the original Ford concept.

By the 1980's some American manufacturers who tried these principles, such as Omark Industries, General Electric and Kawasaki (Lincoln, Nebraska) were achieving success.

Consultants took up the campaign and acronyms sprouted like weeds: World Class Manufacturing (WCM), Stockless Production, Continuous Flow Manufacturing (CFM)

Lean Manufacturing is the term that was introduced by James Womack (co-author of the seminal book: "The Machine That Changed the World") to describe the philosophy and practices under-pining the Toyota Production System (TPS)

In their research into world class manufacturing Womack et al, recognized that TPS was a vastly superior system of manufacturing than that found in most western automotive manufacturers.

Definitions

Lean Manufacturing (also called Toyota Production System, TPS) is a production system inspired by the Japanese concept of kaizen (the strategy of continuous improvement).

Unlike Kaizen, Lean has a focus not only on quality control but also on quantity control to eliminate waste and reduce costs.

There are many definitions and viewpoints for ※Lean Manufacturing§, but the main goal of ※Lean Manufacturing§ is to eliminate waste.

※Waste§ refers especially to excess input materials and useless processing steps. The goal of ※eliminating waste§ may also be stated as providing exactly what the customer values for the lowest cost of production. This will maximize profit per unit.

The word ※Lean§ implies ※cutting the fat§ or ※trimming waste§, where ※fat§ or ※waste§ refer to whatever is not valued by the customer. So another way of expressing the ※Lean Manufacturing§ goal is to only use materials and processes that add value for the customer.

What is ※value for the customer§?

Here is a simple example of what is ※valued by the customer§. Let*s say that you need a supply of nuts and bolts for an assembly operation, so you are the customer for the bolts. You need the size to be correct, but these bolts do not need to be plated or rust-proof or special in any other ways. Therefore nickel plating does not add value to you as a customer, even though it makes a better bolt in other applications.

Further, let*s say you need a supply this afternoon or your factory will shut down. Therefore availability and quick delivery are very valuable to you. You might even pay a premium for express delivery of a one-day supply of already-expensive nickel-plated bolts, while negotiating a discount for a larger supply of standard bolts that your supplier can ship for delivery tomorrow.

In the above example, you, as the customer, place value on having the right size of bolt and timely delivery, but not on nickel plating.

Types of Waste

Three Japanese words defined ※waste§:

• Muda means ※work that does not add value§. The goal is to eliminate processes (and materials) that do not add value from the customer*s view.

• Muri means ※overburden§. The goal is to eliminate inefficient work, whether by better work flow or by working at a pace that the machine or operator is able to sustain.

• Mura means ※unevenness§. The goal is to do work at a steady pace; ※production leveling§ and ※pull production§ are examples of this approach.

The original development of ※Lean Manufacturing§ listed seven types of muda waste. More have been added since then:

• Over-production of well-made goods is wasteful, because the overstocked products will either be sold at a discount or warehoused at some expense. These products may rust or become damaged over time. The goods may be overtaken by technological change and thereby become outdated.

• Excess inventory of raw materials, work-in-process or finished goods is wasteful, because it ties up cash and storage space, whether in a warehouse, on shelves or on the factory floor.

• Unnecessary transportation, whether from one area in a factory to another, between warehouse and factory, or across borders. This especially refers to the transportation of goods when they are not being processed. Transportation costs labor and fuel, and has the potential for damaging goods in transit.

• Re-work to correct errors or damaged goods costs labor, at the very least. Extra material, energy, transportation and wear and tear on machinery may be included. This category should be extended to include duplication of paperwork or data entry steps.

• Wasted motion, particularly through poor human engineering. The minimum cost is time. When personnel have to go through extra motions to accomplish a routine task, the result can be an increase in injuries, or in errors caused by extra fatigue. On the other hand, the tasks must allow enough variety and motion so people do not move so little that they are cramped or bored.

• Extra processing to clarify customer requirements and change the manufacturing orders causes different costs. If caught too late, this leads to re-work or even the rejection of shipped goods. This includes processing beyond customer values or taking extra steps that are not required.

• Idle time, especially if the machine operator must wait for the machine to finish and there is nothing else for that person to do. Some advise using a machine*s idle time for minor maintenance, such as adding a drop of lubricant.

• Defective products returned by the customer have obviously wasted materials and labor.

Batch Size in ※Lean Manufacturing§

※Lean Manufacturing§ tries to reduce batch size to ※one§ as a way of reducing waste:.

• The smaller the size of a batch, the more responsive the factory can be to customer demand, and so it reduces over-production.

• Minimum batch size minimizes inventory requirements.

• Minimum batch size minimizes transportation between warehouses and factories.

• Minimum batch size minimizes re-work if the inspection process is in-stream with production activity. If a defect is found, only that one batch and ideally, only one piece, needs re-work.

• Minimum batch size reduces idle time if an item can move from one process to the next without waiting for a batch to finish ahead of it.

Value Stream Mapping

Value Stream Mapping is a Lean process that follows the manufacturing process to determine which process adds what type of value to the product. In the above example where you need a supply of bolts today, value was added by the milling operations (to cut and thread the bolt) and also by the expedited shipping process. The nickel-plating step added no value. If you had placed your order with enough lead time for regular delivery, then the expedited delivery service would have added no value.

Value Stream Mapping entails following the manufacturing process, including the handling and storage stages, to determine where value is added. For example, storing goods-in-process so that a coating can dry properly is a value-adding step (if the customer wants the coating). Storing finished goods in a warehouse in order to expedite shipping might add value, depending on the time to manufacture and the urgency of a customer*s order. (In the airline industry, for example, ※Plane on Ground§ is the highest priority for manufacturing a replacement part). Storing goods-in-process in a warehouse (because the next machine is busy working on previous batches) does not add value.

Four Functions of Lean Production

1. Production Flow

• Products, workflow, equipment and support

• It is focused on defining products, equipment and workflows that can be produced in small lot production runs being ※pulled* by downstream customer demands

• It is oriented to getting the product to the customer in the shortest period of time and at the lowest cost with superior quality and customer satisfaction

2. Planning

• The separation of:

MRP System function: (Reconciliation 每 the process of high-level demand planning and scheduling) form

Day-to-day planning functions (Regulation 每 the process of regulating command and control sequences within a pull-process environment capable of controlling ※workable work§ for each production unit and production cell.

• MRP must also project intermediate and long-range procurement objectives to suppliers.

• The day-to-day and shift-by-shift operations will need a real-time Plant Operations Control system (POC)

3. Organization

• Lean Production demands a re-thinking of the structure, role and responsibility of each individual within the organization.

• The formation of Production Units operating as ※Business Units§ & Flat Organization will help to understand the needs of their customers and organize all resources, products and capabilities to support and add value to its customers needs and expectations.

4. Performance Measures

• Performance Measures must be developed in a hierarchy that is cascaded upward and downward within the organization.

• The measures should be understandable, simple to administer and enable management and team members to easily make decisions and take action when appropriate.

» More Information