Leading to Lean

The process toward becoming a Lean Enterprise proceeds on three levels through a similar sequence of activities following the Plan-Do-Check-Adjust cycle. The first level is strategic, or company-wide. The second level is plant or location oriented. The third level is process-specific within a location. At each level, an important activity to facilitate planning is to define the current condition with data - establish a measurable baseline for improvement.

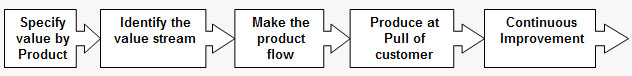

Steps for the Development of the Roadmap to Lean Manufacturing

Phase 1: Specify value by Product

Only the customer can define value (Real or Perceived)

• Steps:

Select initial implementation scope

Define customer

Define value - Quality, Schedule, and Target Cost

• Tools

Quality Function Deployment QFD

• Output

The product, customer, and value all defined so as to allow the distinction between value added and non-value added operations.

Phase 2: Identify the Value Stream

Graphic or visual display of all the systems/processes that make up a value stream as the product flows

• Steps:

Record Current State Value Stream

Chart Product and Information Flow

Chart Operator Movement

Chart Tool Movement

Collect Baseline Data

• Tools

Value Stream Map

Spaghetti chart

• Output

A value stream map that shows the entire information and production process as a system with measures of value added and waste for each process.

Phase 3 - Design Production System

• Steps:

Develop a Future State Value Stream Map

Identify Takt Time Requirements

Review Make/Buy Decisions

Plan New Layout

Integrate Suppliers

Design Visual Control System

Estimate and Justify Costs

• Output

A production system design that is ready for incremental implementation.

Phase 4 - Implement Flow

This phase marks the conversion from a batch and queue type of operation to cellular type of operation.

• Steps:

Standardize Operations SOP

Mistake Proof Processes Poka-Yok

Achieve Process Control

Implement TPM Total Productive Maintenance

Implement Self-Inspection

Eliminate/Reduce Waste

Cross Train Workforce

Reduce Set-up Times SMED

Implement Cell Layout

Implement Visual Controls

• Output

Areas within the production system have implemented processes to ensure that production flow has been achieved. In this state individual areas have managed to reduce a significant amount of waste

Phase 5: Strive for Perfection

The various Lean techniques and tools implemented in earlier phases are repeated and refined taking the improvements to the next level.

• Steps:

Standardize Operations SOP

Optimize Quality

Institutionalize 5S

Institute Kaizen Events

Remove System Barriers

Expand TPM -

Evaluate Against Target Metrics

• Output

The outputs of Phase 6 are incremental, continuous, and generally supportive of the Lean transition process

» More Information