Before an engine will start, it must first be cranked. Turning the engine over draws air and fuel into the cylinders and compresses the mixture so it can be ignited to provide power. Cranking the engine also generates the ignition and crankshaft position sensor signals that are needed to fire the spark plugs and operate the fuel injectors.

So if a starter fails to crank the engine or turns too slowly, the engine will not start. And a no-start means you either walk or bum rides until the problem is fixed (unless, of course, you're a real plugger who drives a vehicle with a stick shift and enjoys the thrill of pushing or roll starting your vehicle.

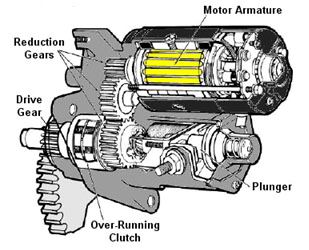

Fig 1. Reduction Gear Starter

Unfortunately, starting problems are not always simple to diagnose. Sometimes the starter motor is blamed for a hard starting or no-start condition that is not the starter's fault. As a result, some starters are replaced unnecessarily. But when the newly installed starter fails to work any better than the old starter, you think the one you bought is no good and take it back.

One way to avoid such predicaments is to bench test old starters to make sure they are defective before you buy a new one. After removing your old starter, you can take it to an auto parts store where they can test the starter's current draw and cranking speed.

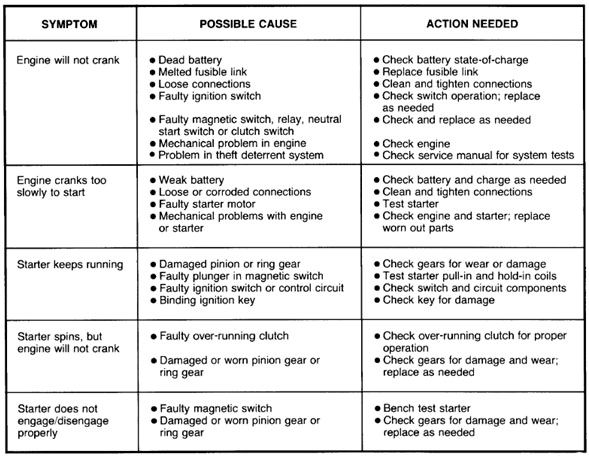

Fig 2. Typical Ignition Switch and Starter Circuit

IS IT REALLY THE STARTER?

Any number of things can prevent an engine from cranking or starting (see troubleshooting chart below). An engine needs the right combination of air, fuel, compression and ignition to start. If any of these is lacking, the engine may crank normally but be hard to start or not start at all.

If nothing happens when the ignition switch is turned to the start position, it may mean the starter motor has failed, or there may be an open in the ignition switch, starter circuit wiring or neutral safety switch on the transmission linkage. Vehicles with manual transmissions have a safety switch on the clutch pedal that prevents the starter from cranking unless the clutch pedal is depressed. Other causes of no cranking may include a bad solenoid, loose or corroded battery cables or even a low or dead battery.

The first thing that should always be inspected is the battery to make sure it has enough voltage to operate the starter. A discharged battery or one that is badly sulfated may not be capable of producing enough voltage or amps to start the engine.

The next check would be the starter motor itself. Using a jumper to bypass the solenoid is a trick that will show if the starter motor spins or not. If the starter works when bypassing the solenoid, the problem is in the solenoid or ignition circuit.

If an engine cranks at normal speed (typically 200 to 250 rpm) but refuses to start, it is probably not the starter - unless the starter motor is pulling so many amps from the battery that there is not enough voltage left to power the ignition system and fuel injectors.

A good starter will normally draw 130 to 150 amps when cranking a four cylinder engine, 175 when cranking a V6, and as much as 200 to 225 amps when cranking a large V8. The current draw depends on the type of starter and the application, so look up the test specs for your vehicle to see if the starter is drawing too much current.

Another test that can be performed on a starter is a no-load free running test with the starter removed from the vehicle. With the starter firmly supported in a large bench vice (do NOT clamp too tightly otherwise you may crush or damage the housing!), use a battery and jumper cables to power the starter. Hook the negative cable to the starter housing, and the positive cable to the battery positive lead on the starter. Most starter motors should spin about 2500 to 3000 rpm. If the starter turns very slowly or not at all, you need a new starter.

If the drive gear mechanism can be replaced separately, there is no need to replace the entire starter, only the drive mechanism (which is often referred to as a "Bendix" drive). This is not recommended on permanent magnet gear reduction starter motors. If faulty, the entire starter should be replaced.

A bad solenoid can also be a source of starter problems. The solenoid acts like a relay to route power directly to the starter from the battery. It may be mounted on the starter or located elsewhere in the engine compartment and is usually connected to the positive battery cable. Corrosion, poor ground at the solenoid mount, or poor battery cable connections will prevent the solenoid from doing its job. Replacement is necessary if the solenoid is defective or stuck open or closed.

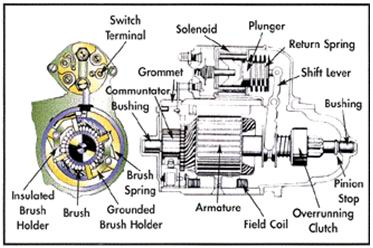

Fig 3. Starter Problems Diagnosis

INSIDE THE STARTER.

The starter motor itself is a high torque direct current electric motor. Inside are a rotating armature, four brushes and a pair of field coils or permanent magnets (on new models). The starter uses the opposing magnetic forces of the armature and field coils or permanent magnets to convert electrical energy into mechanical energy.

Fig 4. The cutaway for a starter motor

When the ignition switch is turned to the start (crank) position, voltage is routed through a solenoid or relay to the starter motor. As the starter motor begins to spin, the drive gear extends and engages the teeth on the flywheel ring gear to crank the engine. When the engine starts and the key is released, the drive gear retracts and the starter stops spinning. An overrunning clutch in the starter drive prevents the starter from being over-revved and being damaged when the engine starts.

Though most starters are "direct drive," some have an extra set of reduction gears to increase cranking torque. Reduction gears also allow a smaller, higher speed motor to be used. Reduction gear starters are often found on Chrysler and import applications.

Cranking an engine is hard work and pulls a lot of amps out of the battery. The cranking load is even greater during cold weather because low temperatures thicken the viscosity of the oil in the crankcase and increase drag. At the same time, the battery has less amps available because cold temperature slows down the chemical processes inside the battery that release stored electrical power. So if the starter has worn internal components, a poor ground or positive cable connection with the battery, or the battery's level of charge is low, the engine may not crank fast enough to start or it may not crank at all.

STARTER PROBLEMS

Starter problems can be caused by worn brushes (carbon pads inside the motor that supply current to the rotating armature), by shorts or opens in the armature or field coils or by worn bushings that increase drag or allow the armature shaft to rub against the pole shoes.

Continuous and prolonged cranking is very hard on a starter because it generates excessive heat. If not allowed to cool every 30 seconds or so for at least a couple of minutes, the starter will be damaged by continuous cranking. Fuel injection has reduced the strain on starters because it takes fewer cranks for the engine to start. Consequently, starter sales for newer vehicles with fuel injection are much lower than those for older vehicles with carbureted engines.

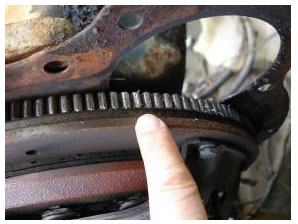

If you hear the starter motor grinding when you attempt to start the engine, but the engine is not turning over, the starter drive may be damaged, or the teeth on the flywheel may be damaged or broken, preventing the starter from cranking the engine. If you suspect damaged teeth on the flywheel, make sure the key is OFF, then turn the engine over about 1/4 turn by hand (grasp the fan to turn the engine). Then try the starter again. If the engine cranks at least part way, that confirms the starter is working but the teeth on the flywheel are damaged. To fix the problem, the flywheel will have to be removed so the starter ring can be replaced. If the teeth are part of the flywheel, you will have to replace the flywheel.

Fig 5. Watch out for damaged teeth on the flywheel.

If the starter can't engage the flywheel, it can't crank the engine.

If the starter cranks the engine normally, but you hear a grinding noise after the engine starts, the starter drive may be hanging up, preventing the starter drive gear from retracting away from the flywheel. This can damage both the starter drive gear, the starter motor and the teeth on the flywheel.

STARTER REPLACEMENT TIPS.

When you need a starter, the replacement should have the same or higher cranking capacity as the original. Most quality replacement starters meet this criteria, but some may not because of over-consolidation. Just because a starter fits a particular vehicle application does not mean it has enough muscle for reliable cold starting. So in addition to matching bolt patterns, drive gears and electrical connections, it is also important to match power ratings, too.

To receive proper core exchange credit for your old starter, make sure the old starter is complete and is the correct one for the application. Reduction gear starters and permanent magnet starters usually have significantly higher core values. Also, be careful when handling permanent magnet starters because the magnets are brittle and can be easily cracked.

One item you should also replace along with the starter on older high mileage vehicles is the solenoid (if not included with the replacement starter). Solenoids wear too, so replacing this component will help assure reliable starting.

You might also need new battery cables if the old ones are damaged or badly corroded. It is important to make sure the replacement cables are heavy enough to handle the amp load because some inexpensive battery cables use undersized wires to reduce cost. Also be sure to check the engine's ground straps. These straps ground the engine to the chassis. Corroded or loose ground straps create a poor electrical connection and can cause slow cranking speeds.

The smaller the diameter of the wire, the fewer the amps it can carry. New ground straps may also be needed if the original straps are missing or damaged.

Lastly, a more powerful battery with a higher cold cranking amps (CCA) rating may provide some added kick for reliable cold-weather starting. The average battery only last about four years, so if the original battery is more than four years old, chances are it may need to be replaced.

If the vehicle also has any weaknesses in the charging system, these problems should be addressed too when the starter is replaced. A weak alternator may not be capable of keeping a battery fully charged, and without a full charge reliable starting may not be possible during cold weather. Replacing the alternator and drive belt may also be recommended if this is the case.

STARTER INSTALLATION TIPS.

On certain older GM applications, the starter has to be shimmed when it is replaced so the starter drive and flywheel line up properly. Reusing the old shims is no guarantee the alignment will be correct. The installer should measure the drive gear to flywheel clearance to determine the correct shims to use.

Many starters also have a heat shield over the motor to protect it against heat from a nearby exhaust pipe. The shield should always be installed to keep heat away from the motor. Failure to do so may cause the motor to fail prematurely, or lead to hot starting problems.

Both battery cables should be removed, cleaned, inspected and retightened. The same goes for the cable connections on the solenoid if it is separate from the starter.

For more information on vehicle electrical systems, please check out the lots more information in RIBO Parts Articles.