By Kuniyoshi Takahashi

Q. The production items at our factory consist of a mixture of prospective production items and sales production items. Amongst our regular prospective production item production schedule it is necessary to intermingle JIT (Just in Time) sales production items as well so creating the production schedule is extremely troublesome. Isn't there a good way of making a JIT schedule?

Create a JIT Schedule by Mixing Backward Scheduling and Forward Scheduling

A. In the case where you are mixing prospective production items and sales production items, it is necessary to create a JIT production schedule that considers the finite capacity of your machines and protects the due dates of your sales production items. Furthermore, because it is necessary to keep your inventory as low as possible it makes the production schedule even more troublesome.

It is possible to create this kind of JIT production schedule, where you want to mix backward scheduling (JIT) and forward scheduling, if you use a production scheduler.

First of allӢprospective production business is simply put as the following situation: This week I want to produce 15,000 units of Product A. The lot size of Product A is 5000 so we'll split it into 3 lots of 5,000. Let's say that the EST for these three will be 5th Nov, 7th Nov and 9th Nov.

Let's try to actually schedule this with a production scheduler. First of all, just like £Ń£± Scheduler Diagram 1 define the processes, next set up the three lots (Scheduler Diagram 1). Based on this data the result of the made schedule is Scheduler Diagram 2.

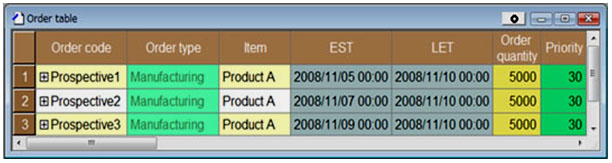

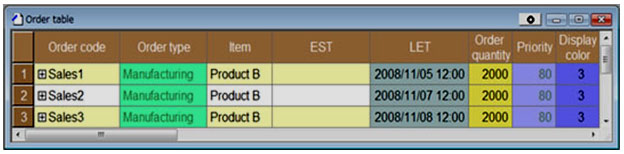

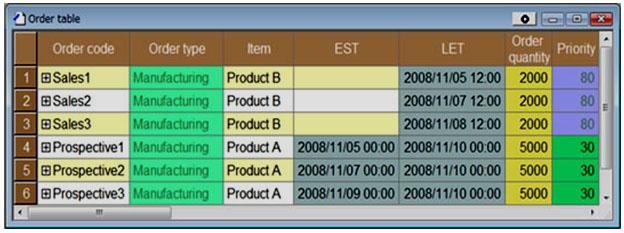

Scheduler Diagram 1: Order set up

In the case where Product A has been set up as prospective production. Set up 3 orders. Split up Product A into 3 lots of 5000 and produce. The EST is the time that Process 1 for that order can start. A priority of 30 is specified for forward scheduling.

Scheduler Diagram 2: Production schedule result

Prospective production item's production schedule. Possible to split Product A into three times and schedule for one week. This schedule is not JIT.

In production management terms this is called forward scheduling.

Next, the sales production item (JIT item) has the following situation: An order has been received from a customer who wants Product B in three shipments of 2000 units delivered on 5th Nov, 7th Nov and 8th Nov. When should each of these be started?

Let's schedule this with a production scheduler. When we set up the order like (Scheduler Diagram 3)Ӣthen the result of this production schedule based on this data will be like Scheduler Diagram 4, a JIT schedule.

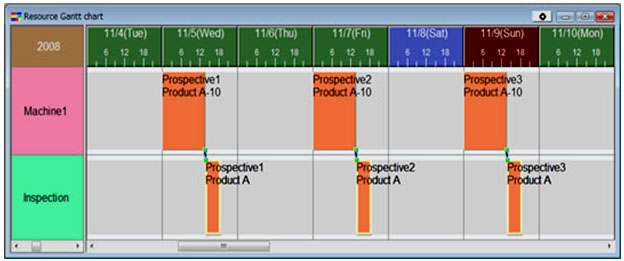

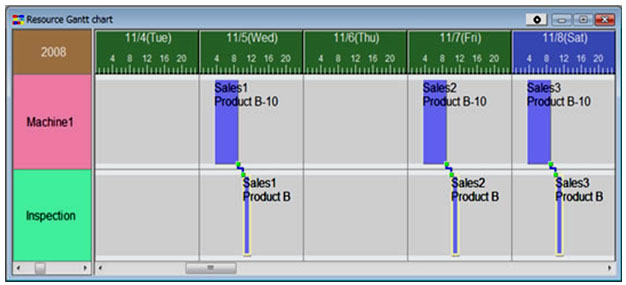

Scheduler Diagram 3: Order set up

In the case that you set up sales production item (JIT item) Product B: Enter the order for Product B in three shipments of 2000 units to be delivered on 5th Nov, 7th Nov and 8th Nov. Specify a priority of 80 for backward scheduling (JIT)

Scheduler Diagram 4: JIT production schedule

The sales production item (JIT item) production schedule. The three orders are assigned so that each of them finishes precisely on their respective specified due dates to become a JIT schedule.

In production management terms this is called backward scheduling. The schedule is made so that the order's final process is assigned so that it finishes on the LET (due date) with the previous processes being assigned in order to pack in towards the right.

Due to this we know when we should start the orders so that they finish just before the due date. In this way we can do a JIT schedule.

In order to mix these two types of scheduling on the computer we only need to combine the order set up so it's simple (Scheduler Diagram 5). In this way, the result of the scheduling is like Scheduler Diagram 6.

Scheduler Diagram 5: Order set up

The state of Scheduler Diagram 1 and Scheduler Diagram 3 orders being combined together. The prospective production item orders (bottom three lines) Ӣhave a priority of 30 and the sales production item (JIT item) orders (top 3 lines) have a priority of 80. This specifies that the sales production item (JIT item) orders take priority and are assigned first.

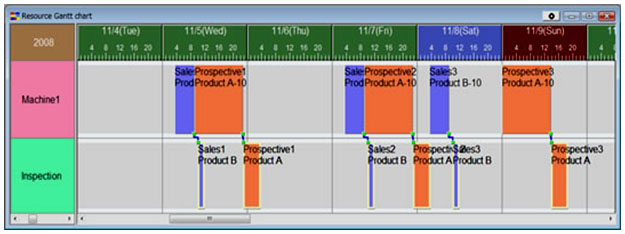

Scheduler Diagram 6: Production schedule result

The sales production item (JIT item) orders are assigned so that they finish exactly on their respective due dates (LET). Prospective production item orders are assigned to the remaining free areas available for Machine1. In other words, sales production items (JIT items) are strictly JIT scheduled to their due dates. You can't say that finishing earlier than the due date is JIT.

In this schedule the backward scheduled (JIT) orders are assigned first and then after that the forward scheduled orders are assigned to the remaining open places.

Due to this it is possible to mix in the assignment of forward scheduled orders whilst still protecting the due dates of the backward scheduled (JIT) orders.

In this way, a production scheduler will follow the setup and process it so it's possible to easily test a JIT schedule. After that, you only have to increase the volume of actual data and test it. Recently, trial versions of production scheduling software are being distributed for free so it's possible to actually enter real data and try JIT scheduling for yourself.

» More Information