Kaizen is the phase where the continuous improvement activities will take place.

When we say "Kaizen" we don't mean just improvement workshops or quick hit improvement teams -

The meaning is taken from the Japanese words kai and zen where kai means change and zen means good.

The popular meaning is continual improvement of all areas of a company not just quality or performance.

This is the phase where real changes will be made, from cultural changes and partnership processes through the implementation or upgrading of key HR policies right up to putting in place real visual, physical initiatives such as -

PMS (Performance Management System) Performance Management is a structured visual approach to monitoring the business performance.

This will have the effect of: Making your performance visible, driving you to take action and provide timely feedback on the effects of your actions

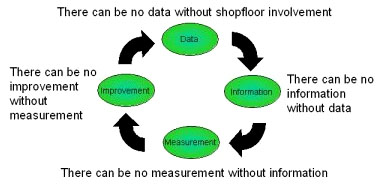

Fig 1. How Performance improves with Management.

Performance Management relies on gathering accurate data about

how processes perform in order to stimulate improvement activity

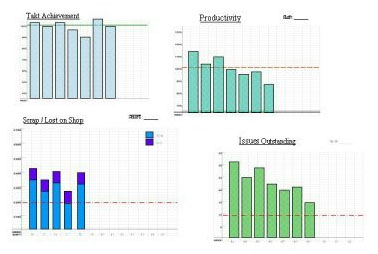

Some typical PMS measures

Fig 2. Performance Management Indicators

Standardized Work

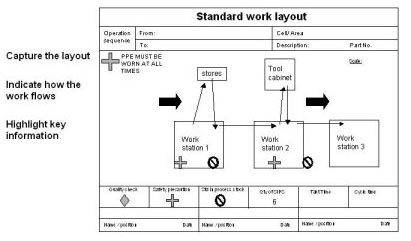

Standardized Work delivers customer satisfaction through a stable, repeatable process.

This ensures consistent Safety, quality, cost & delivery in a standard working environment.

Fig 3. Standard Work Layout

TPM (Total Productive Maintenance)

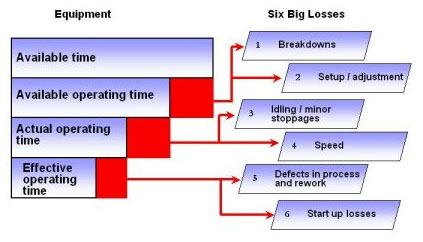

A system of maintenance covering the entire life of the equipment and the total human resource.

TPM is a tried and tested way of eliminating waste.

It is a long term process to increase skills, raise efficiency and work toward zero losses.

Fig 4. Loss Elimination through TPM?

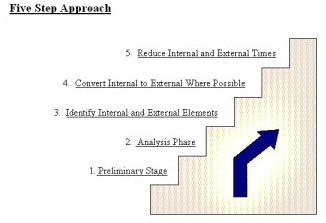

SMED / Quick Changeovers

Quick Changeover is a method of analyzing and reducing the time needed to change a process from producing one good part to producing the next good part

Fig 5. SMED

5S / 5C

5S / 5C is a systematic approach to workplace organization. Encouraging ownership and self discipline to sustain and further develop the working environment.

It aims to:

Remove waste from the workplace, provide an environment where continuous improvement is embraced, improves safety and increases quality.

Fig 6. Workplace Organization

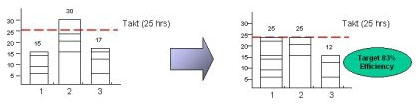

Line Balancing

The even distribution of human work across a production area.

The work is balanced to ensure that overburden and waste are avoided.

Fig 7. Simple Line balance example

Deciding which of the above, or which other lean / kaizen tool to use will become clear from the diagnostic that was carried out in the earlier phase.

You will use the appropriate tool for your problem priority 每 Deploy the tool to cure what*s hurting your business right now.

Ultimately, eliminating all of the 7 wastes is the end goal of Kaizen

Remember, Change for the good = Kai - zen

» More Information