Introduction

• Kanban means 'Display card', Signal, 'visible record' or 'Instruction card' in Japanese.

• Kanban "Card or other device" and systems are used to synchronize the flow of parts in systems (often manufacturing and assembly) where many different parts come together at various points in a long and often complex process.

• This system communicates demand for work or materials from the preceding station

• It is a Paperless production control system where authority to pull, or produce comes from a downstream process.

• Cards can, of course, be replaced with electronic system can be used to inform the upstream process in real time of parts usage.

• Imagine a supermarket, where there are cards attached to all items on shelves.

• At the checkout, the cashier takes the cards off the items and sends them to the warehouse, who send replacement items.

• The warehouse also uses the same system, and when an item is picked off the shelves, the card attached to it is sent further back upstream.

• Consumers pick a product leaves the kanban. This isolated kanban become an order for a new product to replace the one which was just picked up.

• This is a pull system, where consumption of an item leads to the kanban card associated with it being used to 'pull' replacements from upstream in the process.

• Kanban thus leads to less stock-outs and stock-overflows, with the attendant cost savings and more reliable system.

• BUT synchronizing an entire system, as the use of kanban does, only works if you can predict demand and manage the changes in it.

• High stock levels may have masked seasonal swings from upstream producers (bullwhip effect), but in a synchronized system, they now will have to cope with this effect.

• Can use different methods to trigger replenishment activity:

Kanban Cards are the most common

Kanban Containers are frequently

Bar Coding of cards / containers helps when automating kanban systems

Kanban Preconditions

• High demand rate

• Small variations in demand

• Limited number of product variants

• Good supplier relations

The smoothing of production is the most important condition for production by Kanban and for minimizing idle time in regard to manpower, equipment, and work-in-process. Production smoothing (heijunka) is the cornerstone of the Toyota Production System.

Kanban Limitations

• Unleveled demand

• Long setup times or lead times

• Expensive parts

• Large items

• Items with non-frequent usage

• Items with ¡°non-willing¡± suppliers

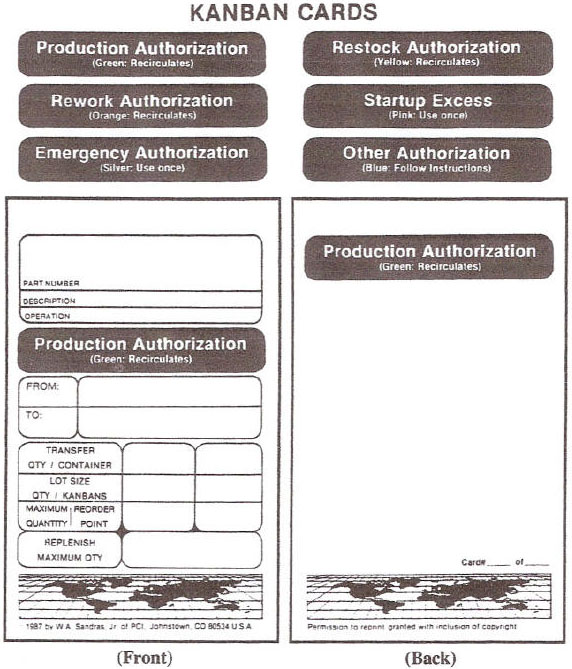

Types of Kanban Cards

Move Cards (or C-Card) (Yellow)

(Conveyance or Withdrawal kanban cards)

• It signify that a part has moved, but has not been consumed

• This may Trigger movements upstream, but not production of a new part.

Production Card (or P-card) (Green)

It indicates that the part has been consumed and will Trigger production of a replacement part.

• A kanban card is physically located on the product, or waiting for it at production

• No kanban in front of machine means no order, so no production.

• Kanban(s) in front of machine means as many orders as kanban cards, so production is required for equivalent quantity.

• As soon as a product is manufactured, kanban is associated.

• When the product is "pulled" or "purchased" by the customer "internal or external" the card is removed and re-circulated back to the beginning of the production process.

There are also sub-categories of these types.

Signal Card (or Material)

It is a type of Production Card that can be used to flag low stock levels and thus trigger purchases.

Supplier Card

It is one that goes directly to a supplier and enters their kanban system.

Special Situation Kanbans

Rework Authorization Kanban (Orange)

• When an item is returned to the production area for rework after the Production Authorization kanban has been removed, the Rework Authorization kanban may be used.

• The Rework Authorization kanban helps limit the amount of rework and provides a visual feedback on the amount of rework in process.

• If a large mass of orange color is visible on a wall in the rework area, we know that not much is in rework.

The Startup Excess kanban (Pink)

• The Startup Excess kanban is helpful when first converting over to kanban control.

• Production Authorization Kanbans are used to authorize items in production up to the limit calculated.

• In many instances, however, when a company is beginning Just-in-Time, inventory in production exceeds the kanban ceiling.

• The excess in inventory needs to be identified until it can be used up.

• Failure to authorize each item in inventory at the start will make it difficult to see which items without" a kanban exist due to prior conditions and which have been created in violation of the kanban control process.

• It is easier and more consistent if everything has a kanban authorization from day 1.

• When a product with a Startup Excess kanban is "purchased" by the customer, the kanban is not re-circulated, because we do not want to replace excess inventory.

The Other Authorization kanban (Blue)

• The Other Authorization kanban (blue) is used for very special instances and temporary usages.

The Emergency Authorization kanban (Silver)

• The Emergency Authorization kanban (silver) is used to allow inventory temporarily to exceed calculated limits.

• Normally it takes at least two higher-level managers to approve emergency kanbans and they are used no more than six times in a twelve-month period.

• When a product with an Emergency Authorization kanban is "purchased" by the customer, the kanban is not recirculated, because we do not want to replace excess inventory.

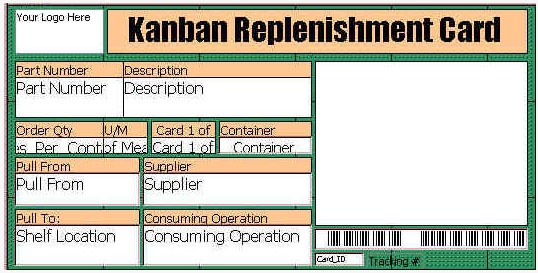

Kanban Data Entry

• A description of the data that goes into each field follows. Most people fill in only a minimum amount of data, thereby avoiding data-entry effort and visual distractions where the information is obvious.

Description:

• Give the description of the part number entered above, that is, the name of the part number or part family authorized by the kanban.

Operation:

• Enter the operation or series of operations authorized by this kanban to occur. That is, enter the operations within which this kanban card circulates.

From:

• For Production, Rework, Emergency, and Startup Excess authorizations, enter the supplier's location of the part to be "purchased" with this kanban.

• For the Restock Authorization, enter the supplier's name and/or location for the replenishment part number.

• The name and location may be for an external supplier, an internal supplier operation/ location, or a stockroom location. When deliveries begin directly to the point of use, simply change the entry from stockroom to the supplier name. For all cards, if the "from" location is obvious or not relevant, leave it blank.

To:

• For Production, Rework, Emergency, and Startup Excess authorizations:

Enter the outbound-kanban storage location where this WIP part number will be placed when this segment of the production process is completed.

The location may be a work position or another point-of-use storage location.

• For the Stock Authorization:

Enter the destination of the replenishment part number.

This location may be a work position or another point-of-use storage location. For all cards, if the "to" location is obvious or not relevant, leave it blank.

Transfer Quantity:

• Indicate the maximum number of kanbans allowed at one work position before movement to the output-kanban location or next work position is required.

• The work position is only for active work, not for storage.

• This field defines the maximum amount of temporary storage that is allowed at the position if it is inconvenient to move each item individually.

• (Usually not required for Restock Authorization.)

Transfer Container:

• Specify the container in which to move the material if a particular container or conveyance type is required.

Lot-size quantity:

• Specify the lot size for this part. When the lot size is accumulated, the kanban (s) must be put in the priority queue to initiate new production.

• (Usually not required for Restock Authorization.)

Lot-size kanbans:

• Specify the number of kanban cards equivalent to the lot size.

• For example, if the lot size is 100, and each kanban card authorizes production of 20 units, 5 kanbans represents the lot size.

• (Usually not required for Restock Authorization.)

Maximum Quantity:

• Required only for Restock Authorizations using the order point replenishment method (i.e. a min./max. or dipstick approach).

• No item is allowed to exist without a kanban ceiling; therefore, specify the maximum allowable inventory for this part at this location.

Reorder Point:

• Required only for Restock Authorizations using the order-point replenishment method (i.e. a min/max or dipstick approach).

• Specify the minimum inventory point at which the Restock Authorization must be submitted to ensure replenishment in the required turnaround time.

Replenish Maximum Quantity:

• Required only for Restock Authorizations using the order-point replenishment method (i.e. a min./max. or dipstick approach).

• Enter the difference between the Maximum Quantity and the Reorder Point.

• This quantity represents the maximum amount of inventory that can safely be replenished without exceeding the allowable level.

• It is permissible to restock less than this quantity, but not more.

• If the full amount is not restocked, the result will be that the Restock Authorization will be turned in sooner next time.

• Ideally, the quantity is a multiple of the supplier-package quantity.

Blank space on back:

• Most often used to affix a bar code to simplify transaction processing and facilitate quality data collection. Sometimes used to show complex routings.

Card #____ of ___:

• Used to identify the sequence number of each kanban card for a given part number or product family.

• Numbering each card will make it easier to know how many exist in the series and will permit detection of an additional or missing card.

• Note that the card design is the same for all types; only the name of the card changes.

• It is possible to use only one type of card, with the heading "Do it!" authorizing production, movement, etc.

• Sometimes, however, color coding can help to simplify the process. Just remember to keep it simple.

• For that reason also, many data fields are left blank if they do not apply or if the information is obvious.

Kanban Disciplines

• Always turn kanban cards in after lunches, breaks, and between shifts to get up to date scheduling every two hours.

• Have a Common Drop-Off Location for cards to be dropped off (Example: break room, restroom or production office).

• Operators on the way back from break or restroom will look at kanban drop off to see if any parts are pulled from their processes.

• If there are cards the operator will return the cards to their work station and place them on the KANBAN BOARD

• Never run over the kanban card amount and never substitute paper notes for kanban cards. If you must run extra parts get overrun cards from the scheduling department.

• It¡¯s always best to run the specified kanban amount.

• Never run machines with set-up times earlier than when the cards are fully up to the GREEN on the kanban board.

• Nothing is made or moved without a kanban card

• Establish a Primary Location for all parts.

• Always fill containers to specified quantity on kanban card.

• If you have a partial container generated at the end of a run, use a partial tag to identify the container and store it away from the Primary Location.

• When that part is set-up on the next run then finish filling the container.

• Always define kanban cards with a color scheme

WIP ¡°Green¡±,

Finished Goods ¡°Yellow¡±,

Overrun Cards ¡°Orange¡±, etc...

• Always start out slow when implementing kanban. Do one machine and then audit that machine for at least two weeks to make sure you have the discipline in the system.

• Train everybody ..This is very important.

• Always start the kanban system simple, then fine tune the system later. If you start a difficult kanban system, it will fail.

• Pass scheduling responsibility to the Operators. This gives process ownership to the people operating the equipment or work center.

• Scheduling personnel should only step in when a designated quantity of parts are in the RED zone on the Kanban Board

• Schedule Overtime based on kanban cards in the RED zone on the Kanban Board

• Only quality parts are sent to the subsequent processes.

• Kanban cards are not to be left on products in the hold area.

• Place a kanban card on all parts in stock when setting up the kanban board on a machine.

• This will tell you where you are at with the schedule on the Kanban board.

Rules for Kanban control

• Manufacturing or assembly may not be initiated without the permission of a production kanban

• Material may not be transported without the permission of a transport kanban

• Only standardized containers loaded with the correct items may be used

• There should be exactly one production kanban and one transport kanban for each container

• Defect details should not be transported to the next station

Kanban Sequence Board (KANBAN BOARD)

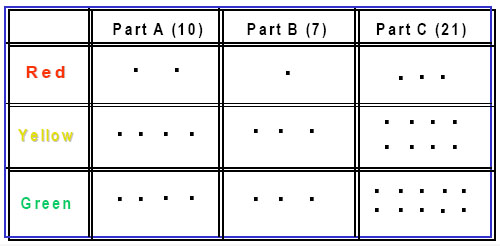

Fig 1 Kanban Sequence Board

• The above figure shows an empty kanban board with hooks for hanging kanban.

• Each column is set up for kanban for that part.

• Shown in parentheses are the maximum number of kanban that have been allocated and thus the maximum number of containers of parts in the system at any point in time.

• A material handler will pick up cards from the consuming operation which represent containers of parts that have are being used in production and bring them to the producing operation.

• The material handler will fill the board by placing the Kanban on available hooks from the bottom up.

• The Green Zone indicates No Rush to make these parts.

• Cards in the Yellow Zone are Higher Priority and cards in the red zone mean the downstream operation may be starved for parts unless you build these right away.

• For example, in the above figure there are 2 hooks in the Red Zone for Part A so someone decided two bins is the Minimum Reorder Quantity.

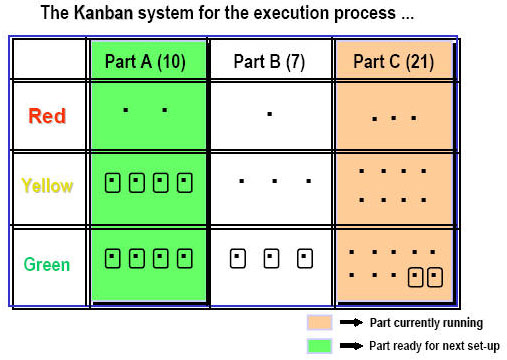

Fig 2 Planning the kanban system

• Figure 2 shows a board loaded with kanban that have been coming back from the consuming operation (e.g., assembly).

• In this case we have color coded the Part A segment of the board with green indicating the cards for Part A are almost into the red zone and production should be set up to make those parts next.

• By contrast, there are only two cards back for Part C out of a total possible 21 cards so there is plenty of Part C in the supermarket and that is the lowest priority for production.

• It should be clear that this simple manual system is literally the Schedule or (Prioritization)

• Automatic Prioritization is possible using a Traffic Light (RAG) system

Fig 3 APS Can Enhance the Kanban System

• Figure 3 illustrates that when conditions change, e.g., customer demand rates (volume or mix or both) change or perhaps there are problems with parts or machines which require more safety stock for some parts, cards should be added or subtracted from circulation.

• In this case conditions changed and the APS systems calculated cards should be reallocated. For example, four more kanban should be added for Part A to increase the maximum WIP of Part A.

• These will be allocated by adding two hooks to the green zone and one each to the yellow and red zones.

• APS recommended the change in kanban and can also recommend how to allocate the kanban (e.g., what should be the minimum trigger point).

• The board and cards can be a very powerful, visual control system which is loaded manually¡ªbut the optimized planning for this can be done by computer almost instantly.

Kanban Process Flow

• Shipping Pull

Shipping department pulls customer containers and removes kanban cards from containers before shipping product.

Shipping Technician returns kanban cards to appropriate machines that product was pulled from, and places cards on the KANBAN BOARD

• When the kanban board hits the green run position on a part, that cell should begin running that part.

Note: (Some cards can be returned directly to previous cell from shipping, and some cards will be returned to a central zone. (Mailbox)

(Example: By restroom where everybody goes)

• When cards are put in a central zone mailbox they will be picked up after break, lunch or in between shifts by the operators of that machine and placed on their kanban board to see if any parts are in the run condition.

• Assembly Pull

When containers are pulled from WIP area (e.g. Press) the cards are pulled from that container in assembly when the container is empty.

The kanban card then is placed in the mailbox by (e.g. Restroom) and picked up by the operators of the previous machine after lunch, break, or in between shifts to be placed on the Kanban board by their machine.

When the cards build up to the Green line at that press, setup and run that job. When a container is complete at the press place a kanban card on the container and move container to primary WIP area for that part.

• Kanban Card Scenario¡¯s

If there are multiple jobs up to the green line (Run status) chose which one to run next by your customer pull.

(Example: If part is directly shipped to outside customer, probably run that one first.)

If multiple cards on multiple parts are in the ¡°Red Zone¡± contact Materials Dept. for assistance on what sequence to run the parts.

• Partial filled containers:

If a container is not quite full due to a insufficient amount of raw material, put a partial tag on that container and store that container in a partial area in the plant.

When the operator sets up on a part that has a partial container the tow motor should go to the partial area to pick up that container, to finish filling the container to the required kanban.

The operator will know he has a partial because the partial tag is not on the kanban board.

• Kanban cards may include instructions to the person upstream, so when they receive the card, they simply move or produce items as instructed.

• A production operator, when receiving a kanban card, will make only as many parts as are in the kanban lot size.

• One card may be attached to a single item or to a number of items, where the number of items in the batch will depend on the variation within the system, the time taken to product items, and other factors.

• An improvement objectives is to reduce the number of parts in the kanban batch or lot size.

• Reducing this size exposes variation and other problems, and so must be linked to process improvement.

One-Card Kanban

• Push Manufacturing and Pull Transports

• This system uses only a Move Card.

• The most common (similar to OP/OQ systems)

• An empty space in the outbound stock point becomes the production order for another container.

When the downstream (pulling) workstation takes a container, the attached kanban is sent back to the upstream workstation to authorize production of a replacement.

• It is appropriate when:

The workstations are close together.

Simple prod with few options e.g. motor bikes

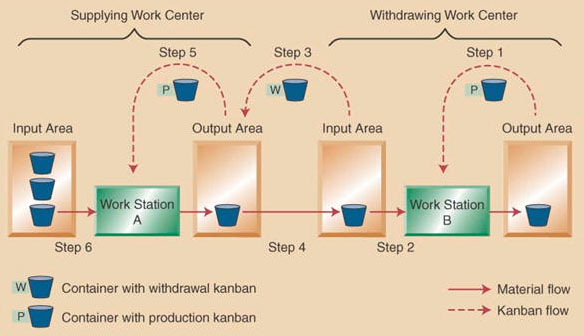

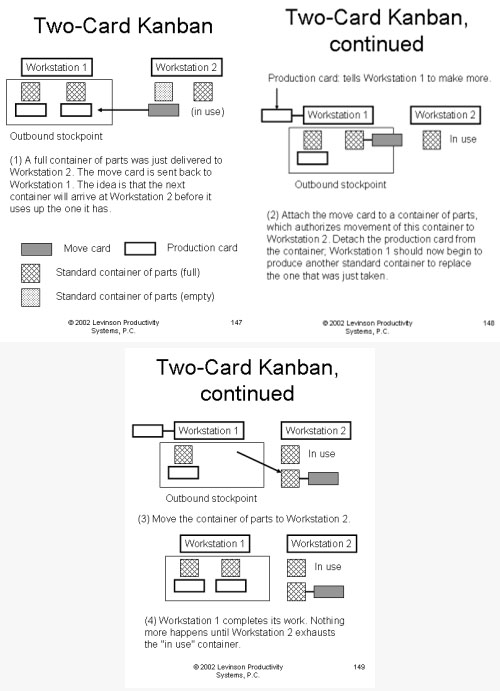

Two-Card Kanban

• Pull manufacturing and Pull transports

• For more complex material flows

• E.g. car manufacturing (many options/variants)

• Uses a Move card and a Production card

• Move card:

Move requests movement of a specific number of units from an outbound stock point to an inbound stock point.

Attached to a standard container of parts when the container is moved.

• Production card:

Indicates that items should be made for use or to replace pipeline stock.

Tells what to produce

Used only at the work center and its outbound stock point.

Suitable when workstations are not close together.

• One card (move or production) stands for one standard container of parts.

• The production card remains at its workstation.

• When a container of parts is taken (pulled downstream), the production card authorizes production of another container.

• When the requesting (pulling) workstation empties a container of parts, return the move card to the supplying operation and attach it to the next container.

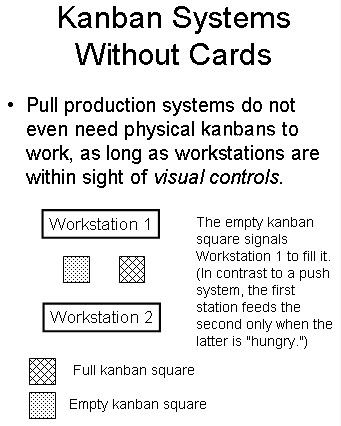

Kanban without Cards

• Kanban-style pull production control can be achieved without using cards. The setup is very similar to a two-bin replenishment system.

Brand-Name Kanbans and Generic Kanbans

A brand-name kanban

• The more familiar type, answers both questions at once: When we receive a free brand-name kanban, we are authorized to immediately ("when") build another identical item ("what")

• If we have hundreds of items with high product- variety environments, brand-name kanban become impractical

A generic kanban

• Generic Kanban authorizes production to begin immediately ('when''), but it does not provide specific information regarding what to build.

• Often the generic kanban will authorize production of an item within a family of parts but will not specify the item or its options.

Determining the number of kanban cards / containers needed for each item

Kanban Quantity (Max.)

K = D (P + C)/ Q + SS

Where:

D = Demand (Consumption Rate in units per time period) Takt Time

P = Production Time per batch (order to replenishment) LEAD

C = Conveyance Time per batch (order to replenishment) TIME

Q = Quantity per Kanban (Transfer Batch Sizes) Order Quantity

SS = Safety stock.

N.B. Kanban Quantity must be regularly reviewed and adjusted

• Typically there is one kanban per container and the container size is then the size of the order quantity.

• Thus, adding a kanban means adding an additional container of parts, that is, work-in-process, in the system. We can see from this equation that:

The greater the takt time the greater the number of kanban.

Takt time will vary across different end products which will require different parts.

The greater the lead time the greater the number of kanban.

Note that the lead time, which is the time required to replenish the marketplace when a kanban has been sent back, includes production time and conveyance time.

Both of these will vary across components and thus different number of kanban are needed depending on lead time.

Capacities of containers also vary depending on the size of the part.

The safety stock depends on how much variability there is in customer demand, manufacturing, and supplied component lead time¡ªthat is, how reliable the processes are.

This also varies across different products and manufacturing processes.

Production smoothing, referred to as heijunka is so critical

When all the marketplaces and kanban quantities are sized to this takt time, a wild swing in demand for a particular product cannot be handled by the kanban.

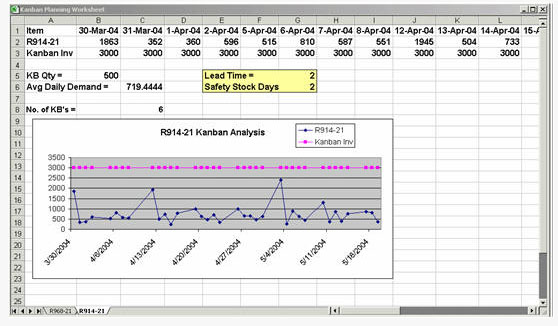

Example:

• An item has a 2 day lead time (when a kanban is emptied it will take 2 days to refill it)

• An item has a 2 day lead time (when a kanban is emptied it will take 2 days to refill it)

• Average daily usage of the item is 50 per day

• You will need 100 within the replenishment lead time (average daily demand times lead time)

• Thus, you need to activate 5 kanban cards (demand during lead time divided by kanban size)

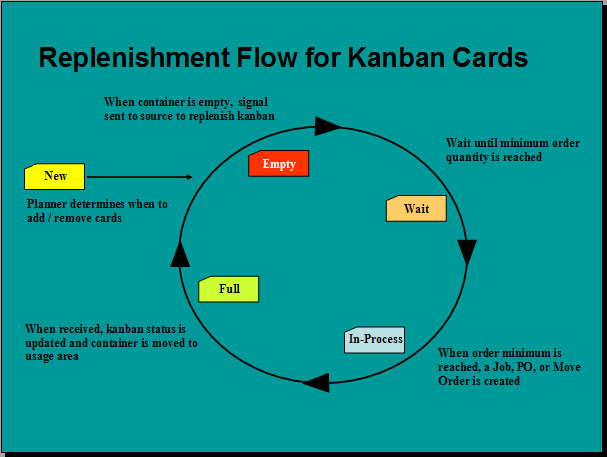

Card Status v.s. Supply Status

Card Status

• Active: kanban card is in the replenishment chain

• Hold: card temporarily removed from replenishment chain

• Canceled: card permanently removed from replenishment chain

Supply Status

• New: kanban just created and not yet part of replenishment chainEmpty: kanban is empty and replenishment signal has been generated - impacts Inter-Org and Supplier source types

• Full: kanban has been replenished and material is available for use

• Wait: kanban is waiting for minimum order quantity to be met by the aggregation of cards.

• In process: For the Supplier source type, PO has been approved. For Inter-Org source type, internal requisition has been approved

» More Information